I started final assembly of the outboard leading edges by first riveting the nutplates to both left and right splice strips. I had previously decided to dimple the nutplate attach holes rather than countersink them as suggested in the plans, but realized that the aft most nutplate attach hole at the ends of each splice strip would interfere with the wing spar step bars when the leading edge was attached.

To remedy this, I flattened out those 4 dimples and instead hand countersunk those holes using the deburring bit to fit a NAS 1097 3-3.5 "oops" rivet. This allows me to squeeze the rivet and still have adequate clearance to not interfere with the spar step bars when the leading edge is attached.

All splice strip nutplate attach rivets were squeezed using the pneumatic squeezer.

|

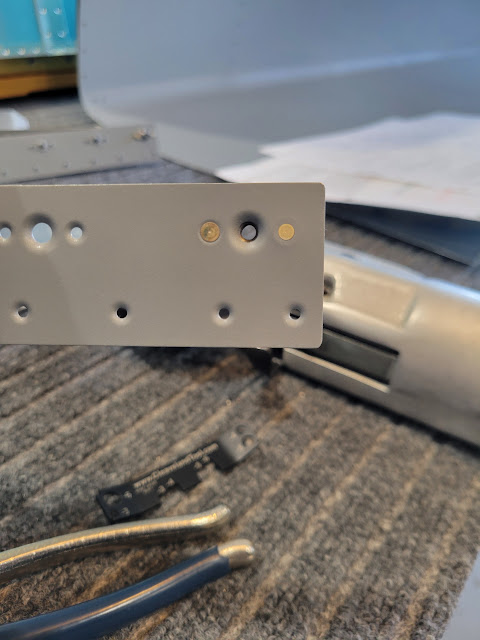

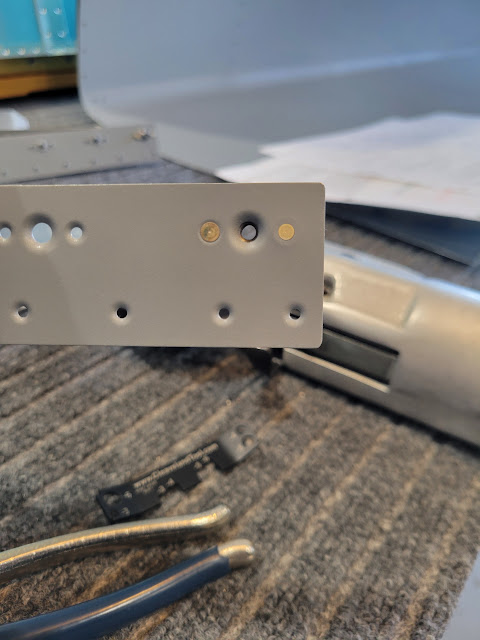

| Aft most nutplate installed in the splice strip. Note the "oops" rivet head is slightly smaller than a standard AN426 rivet head |

|

| You can see the difference in height of the shop head of the "oops" countersunk rivet vs the AN426 dimpled rivet to allow for clearance next to the spar step bar |

|

| Nut plate rivets sit nice and flush in the splice strip. I used 3-4 rivets rather than the recommended 3-3.5 rivets due to having dimpled the nutplate attach holes |

|

| Nut plates attached to both splice strips |

Prior to clecoing the leading edges back together, I decided this would be a good time to enlarge the tie down holes in the skins as I could easily clamp the skins to the workbench for drilling.

However, I had to first drill a hole into the workbench that would allow me to drill through the skin. I did this using a portable drill press with a 7/8" forstner bit.

|

| Hole in workbench that allows me to use the step drill with pieces clamped to the workbench |

After clamping the skin in place, I used the step drill to drill an 11/16" tie down hole (same size as the tie down hole that was drilled in the tail cone), deburred the edges and added touch up primer on the interior surface.

|

| Outboard leading edge clamped to workbench with tie down hole centered over the workbench drill hole |

|

| Step drill used to enlarge tie down hole. The clamped skin stayed perfectly positioned, and cleaning up metal shavings is much easier now than when the leading edge is assembled |

|

| Close up of enlarged tie down hole with edges deburred and primed |

Next I assembled the right outboard leading edge in the cradles and started riveting from the aft end of each rib. I used a level across the top to ensure that there was no twist in the leading edge.

|

| Right outboard leading edge clecoed together in cradles clamped to the workbench, ready for riveting |

|

| I left space behind the leading edge assembly so that I could slide it back and forth across the workbench to rivet both sides evenly |

The plans recommend riveting the skins to the ribs starting from the aft end and working towards the leading edge. When removing the aft most cleco, the skin had a tendency to pull away from the rib. To keep everything together while setting that aft most rivet, I found that a piece of tape worked well.

|

Blue painters tape used to hold skins tightly against the ribs when riveting the aft most rivets in the leading edge

|

Riveting the first several holes on both sides of the leading edge is relatively easy. There were a few holes that had to be reamed so that the rivet would sit flush, but the rest went in easily.

I used the pneumatic squeezer with the longeron yoke on the inboard end of the leading edge as I had easy riveting access there, and bucking around the nutplates would have been a little tight in places.

|

| Starting from the trailing edge I began riveting down each rib beginning with the center rib |

There is one rivet in each rib that sits under the skin stiffener. Normally, these are hard to buck because you need a bucking bar that will fit under the narrow J-channel. I decided instead to rivet the rib hole just below the one under the skin stiffener, and with that done I was then able to remove the stiffener to get access to rivet the holes that lie under it.

|

| J-channel removed to give easy access to the rivets that lie under it |

|

| With the rivets that sit under the skin stiffener J-channel installed, the stiffener can now be slid back in place |

I then reclecoed the skin stiffener and riveted it in place from the center outwards.

|

| Ready to rivet the skin stiffener |

|

| Top skin stiffener riveted end-to-end |

|

| Shop heads on the stiffener are all within spec and the stiffener sits tightly against the skin |

With the skin stiffener in place, I continued riveting down the ribs towards the leading edge, a few rivets at a time on each side.

The rivets along the bottom flanges of the leading edge ribs were easily reachable, with adequate room on the inside for the bucking bar. I started squeezing rivets along the inboard rib, but also switched to bucking there as I was getting good results.

|

| Bottom side of right outboard leading edge completed |

|

| Final few rivets to set on the forward top side of the leading edge. These are slightly tougher because of the angle at which the rivet gun needs to be held if setting the rivets alone. |

To set the remaining rivets, I decided to take the outboard leading edge out of the cradles and place it on the workbench top side up, with the cradles bracing the leading edge from behind. This allowed me to use gravity to my advantage and made it easier to reach over to the leading edge rivets. This worked really well and all the rivets were set perfectly!

|

| Leading edge laying on the workbench as I set the remaining rivets. These require some reaching over to get the rivet gun at the correct angle, but I felt I had good control the whole time. For these rivets I used a 3/4" Boeing flush set which is smaller but has less tendency to slide over curves than the 1" Boeing flush set. |

|

| Right outboard leading edge complete and ready to attach to the main spar |

Build Hints

- The nutplate holes at the aft edges must be countersunk for rivets so that they clear the main spar step bars when attaching the outboard leading edge to the main spar. All other nutplate holes can be dimpled for riveting if preferred. I used NAS1097 "oops" rivets in the aft nutplate holes so that I would not need to countersink the hole that much.

- In hindsight I'm happy I enlarged the tie down hole while I could still clamp the leading edge skins firmly to the workbench. I felt that once assembled, the skin was a little too flimsy to have resulted in a clean hole had I used the step drill at that time. YMMV!

- Put towels, rags, blankets etc in the bottom of the leading edge skins while riveting just in case a bucking bar is dropped in there!

- After riveting rib holes at the aft ends of the leading edge, the skin stiffener can be removed temporarily to set the rib rivets that would lie under the J-channel. Afterwards, the skin stiffener can be replaced and riveted in. This saves having to use a tight-fit bucking bar in the small area under the J-channel to set those rivets.

- Use gravity to your advantage while riveting the forward most top holes by laying the leading edge down after having completed riveting the bottom side.

Time Taken: 11.1 hours

Dates: April 19 - May 8 2024

Wing Outboard Leading Edge Total Time: 39.3 hours

RV-10 Build Total Time: 658.1 hours

Priming Total Time: 80.0 hours (not included in build time totals)