Priming - Wing Outboard Leading Edge 17-3-10

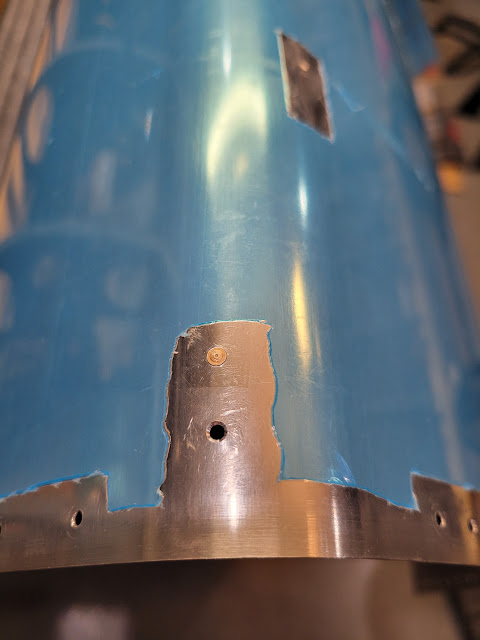

With all outboard leading edge parts dimpled, I moved on to priming them. Nothing complicated here, just had to keep track of the position of each rib in the leading edge using tags. Right outboard leading edge ribs, skin stiffeners and splice plates prepped with EkoEtch Outboard leading edge internal parts primed with EkoPrime. Only the left leading edge ribs remain to be primed. Since the weather was perfect for priming, I also took time to prep and prime the outbaord leading edge skins. Skin ready for cleaning with EkoEtch Right outboard leading edge skin etched and ready for priming Left outboard leading edge skin etched and ready for priming Outboard leading edge skin primed Left leading edge ribs primed. Now all parts in both leading edges are ready for final assembly Primer used: ~380g + 38g distilled water Time Taken: 6.6 hours Dates: April 11 - April 21 2024 RV-10 Bu...