Elevators 9-1 to 9-2-7

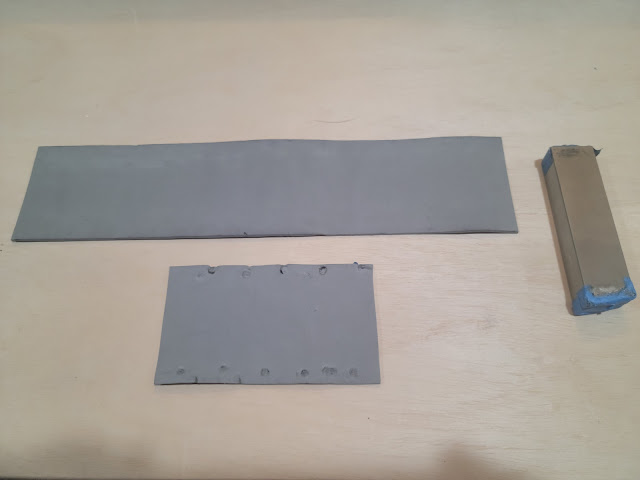

Starting on the elevators, I began by marking and cutting the 16 E-1008 elevator rib parts into pieces using the bandsaw. I then deburred all the edges using the bench grinder wheels on edges that I could easily reach, and then a scotchbrite wedge attached to a dremel for the remainder of the edges. With everything deburred, I clecoed the ribs together and made sure the parts were labeled correspondingly. There was no need to final size the 1/8" holes as they were already final sized. 16 ribs, 8 per elevator I then moved on to preparing and constructing 2 tip rib assemblies. This involved ensuring the tip rib flanges were at 90 degrees to the web, and fluting the flanges as required to straighten the ribs. Fluting was crucial here because otherwise when the ribs were clecoed together with the counterbalance skins, the holes would not line up if the ribs were not straight. Ultimately, the fluting was not hard and the smaller tip ribs actually came already fluted and straightened, s...